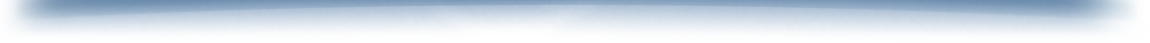

Method of guided waves is ultrasonic inspection method of extended objects. Usually, when monitoring torsional low frequency waves are used. The feature of the torsional wave: group velocity is independent of frequency (see picture 1), i.e., the dispersion is not observed, and the low frequency allows waves to propagate over long distances.

Picture 1. Dependence between group velocity and frequency

Torsional waves (torsional waves) were known in the late 50s of the last century, however, the possibility of using low-frequency ultrasound to monitor the extended objects, such as rails, pipes and rods, appeared only in the late '80s thanks to the development of computer technology. First mathematical model of guided waves for inspection of pipelines presented professor at Imperial College UK Michael Cowley in 1986 and 10 years later, together with Dr. David Alleyne, they created the first device to control pipelines - Wavemaker SE16.

In 2004, Guided Ultrasonics Ltd has released a new device Wavemaker G3, much advancing its predecessor SE16.

LLC JV «Technical supervision Company DIEKS» since August 2005 successfully applies Wavemaker G3 with technical diagnosis pipelines for various purposes, and since August 2012 - the latest development of Guided Ultrasonics Ltd - Wavemaker G4.

Method of guided waves designed primarily for control of hard to reach areas in pipelines, such as transitions in boxes under the railway and roads, underwater crossings, areas at a height, underground and walls.

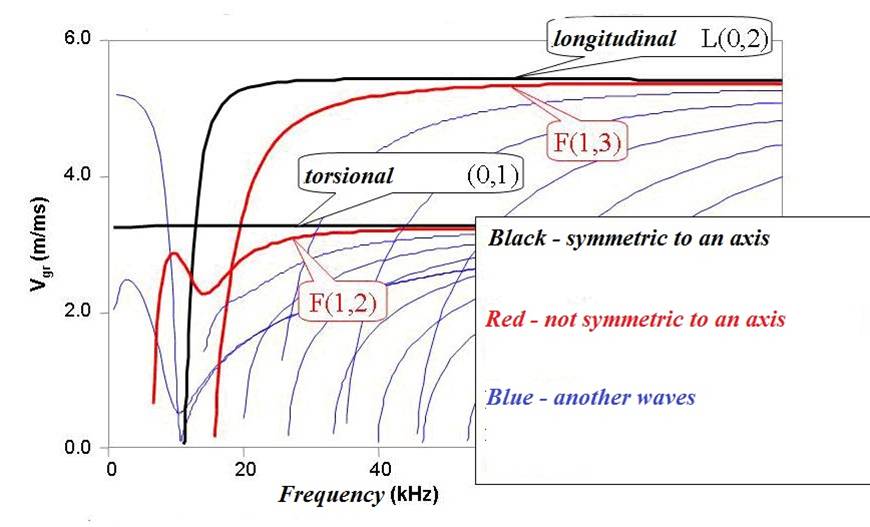

Typical test configuration

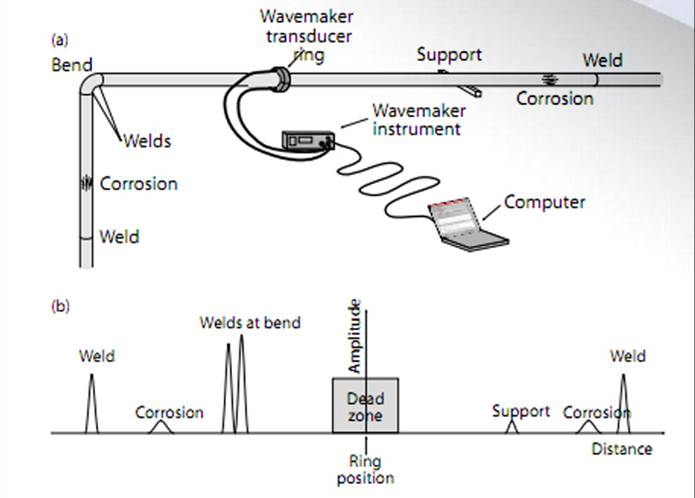

Schematic diagram showing the clearance that is normally required around a pipe

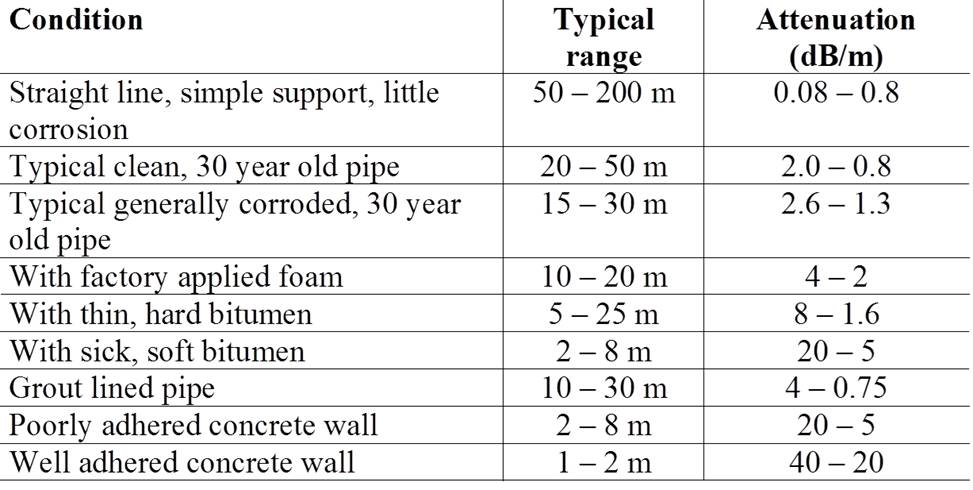

Average length of pipes that can be inspected from one location (in either direction) in the standard frequency regime. Associated average attenuations are also given for reference

The method of guided ultrasonic waves can detect following defects:

- internal corrosion damage;

- external corrosion damage;

- nonmetallic inclusions;

- defects in welds;

- erosion damages in bends;

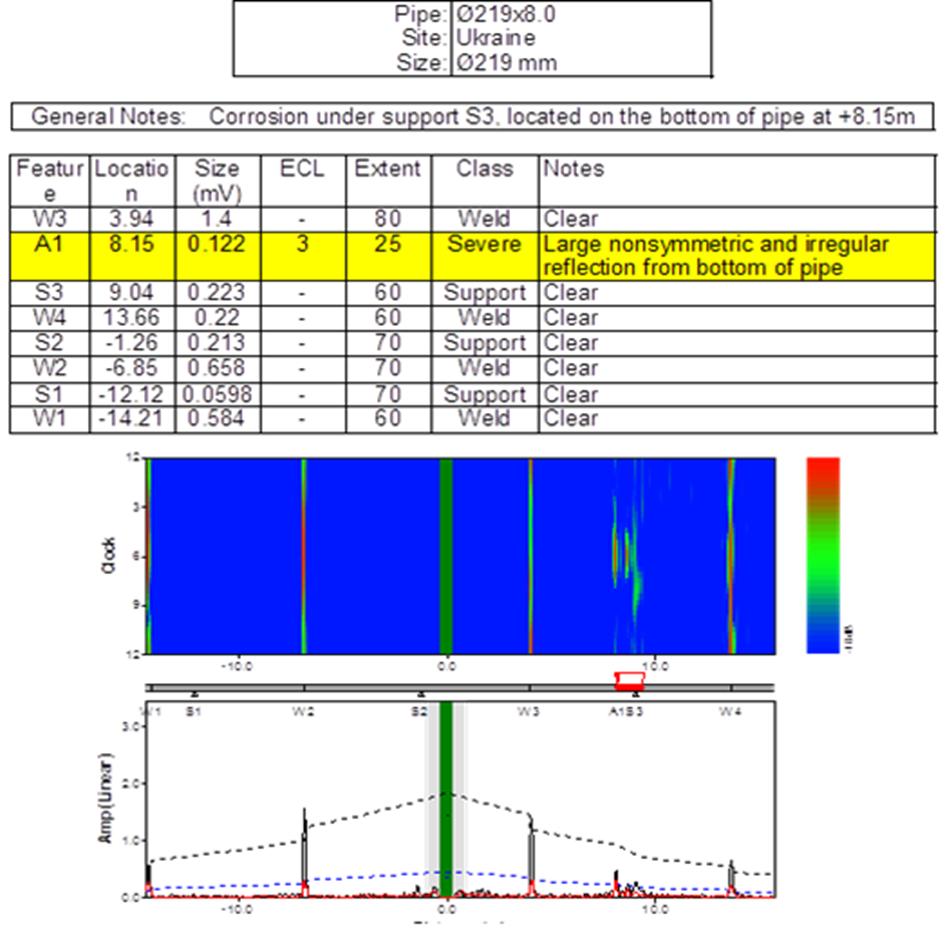

- corrosion under supports;

- cracks in welds and solid metal;

- laminations.

Advantages of the guided waves method:

- not needed disconnection of the equipment at the time of diagnostics;

- minimized costs of preparing for the testing;

- time savings and high reliability of the identification of potentially dangerous areas of the pipeline;

- time saving on carrying out the technical diagnostics;

- opportunity to assess the technical

condition of inaccessible areas of the pipeline;

Getting a complete picture of the technical condition of the pipeline allows easier, faster, and more valid expert conclusion about the suitability of the test object for further operation.

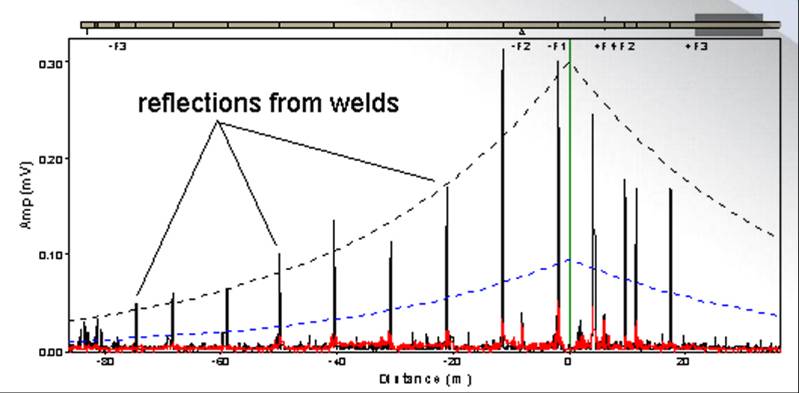

Testing results

Depending on the condition of the pipeline, isolation type and damping areas, the length of testing area can be from 5-10m up to 180m in each direction from the place of the test point

Our company has the special gauge and test stand, where specialists by the method of guided waves explore optimal modes and hardware configuration for the determination of certain types of damages. Also stand is used for practical training with teachers Guided Ultrasonics Ltd.