Metals used in thermal engineering, are subjected to mechanical tensile tests, hardness and toughness. Welds were tested for tensile, toughness, bending or flattening.

Machine parts and elements of steel structures often perceive shock loads. Strength of the material defined for smooth loading, cannot give an idea about the performance of the material under dynamic loads. Metal can be very strong with static loads and at the same time easy to split from the blows.

During tensile test samples are stretched by two gradually increasing forces to be applied strictly along the axis of sample.

Photo 1

Photo 1 shows a machine MP-200 designed for testing metals in tension. Round and rectangular samples are fixed in the grips of various configurations. The upper jaw is associated with the force measuring device. Measurements received shall be made and processed on the computer.

Both flat and circular samples are used to test the weld tensile, a working part of which includes the entire thickness of the weld. The sample weld must necessarily hit the zone in which the welding process was held or recrystallization of the metal occurs. Strengthening of weld, backing rings and residues should be removed with the base metal.

The maximum tensile force is related to cross-sectional area of the sample before the test and thus tensile strength of the welded joint is determined.

On samples cut from the welded joints (and entire test of welded joints), only the tensile strength is defined. It should not be below the minimum tensile strength allowed by the standard or specification for the base metal.

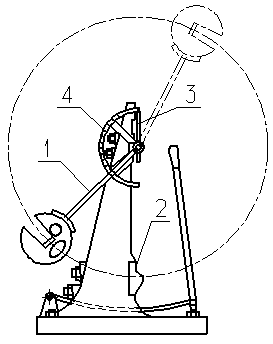

To determine the ability of the base and weld metal or weld joint perceive dynamic load toughness tests are held. To test the toughness square sample is applied. It is destroyed on pendulum. The sample is mounted on special supports. Before the test, the pendulum is raised up at an angle α and fixed. Then the pendulum is released, it falls, hits the side of the sample 2, opposite to the notch. Sample is destroyed, and the pendulum goes on, leaning at an angle β from the vertical axis.

Picture 1. Pendulum for toughness testing:

1 - pendulum; 2 - sample; 3 - arrow; 4 - scale.

Picture 2. Position of the sample while testing.

The toughness is determined for the samples of the weld metal or heat affected zone. Toughness tests of welded joints are held for pipes having a wall thickness greater than 12 mm [if they are working with superheated steam at a temperature higher than 450°C or hot water at a pressure of more than 8 MN/m2 (80 am) and a temperature of more than 120°C] . Samples are cut across the joint and incision is made on the weld metal from the joint opening.

The test is not considered satisfactory if at least one of the samples obtained values are more than 10% over the permitted limits. If the toughness of at least one sample is below normal, the weld quality is considered unsatisfactory.

Hardness - the property of metals to resist the penetration of other, more solid materials. Hardness determines many of the operational properties of the metal wear resistance, cutting properties of the tool for metal working, erosion resistance, etc. Hardness can sometimes indirectly determine the tensile strength and yield strength of the metal without cutting the samples. Most methods of determining the hardness are based on the principle of pressing into a sample harder metal ball, cone or pyramid.

Photo 2

To test the hardness of metals and alloys Brinell hardness tester type 5004 TB is used (photo 2).

According to Brinell, hardness test is performed by pushing hardened steel ball into tested material. After removing the load you can see the imprint from the ball on the surface of tested material, which parameters are then used in the calculations.